- Homemade Bandsaw Sawmill Plans Free

- 14 Bandsaw Sawmill Plans Download Free

- 14 Bandsaw Sawmill Plans Download Free

- Bandsaw Sawmill Plans Free

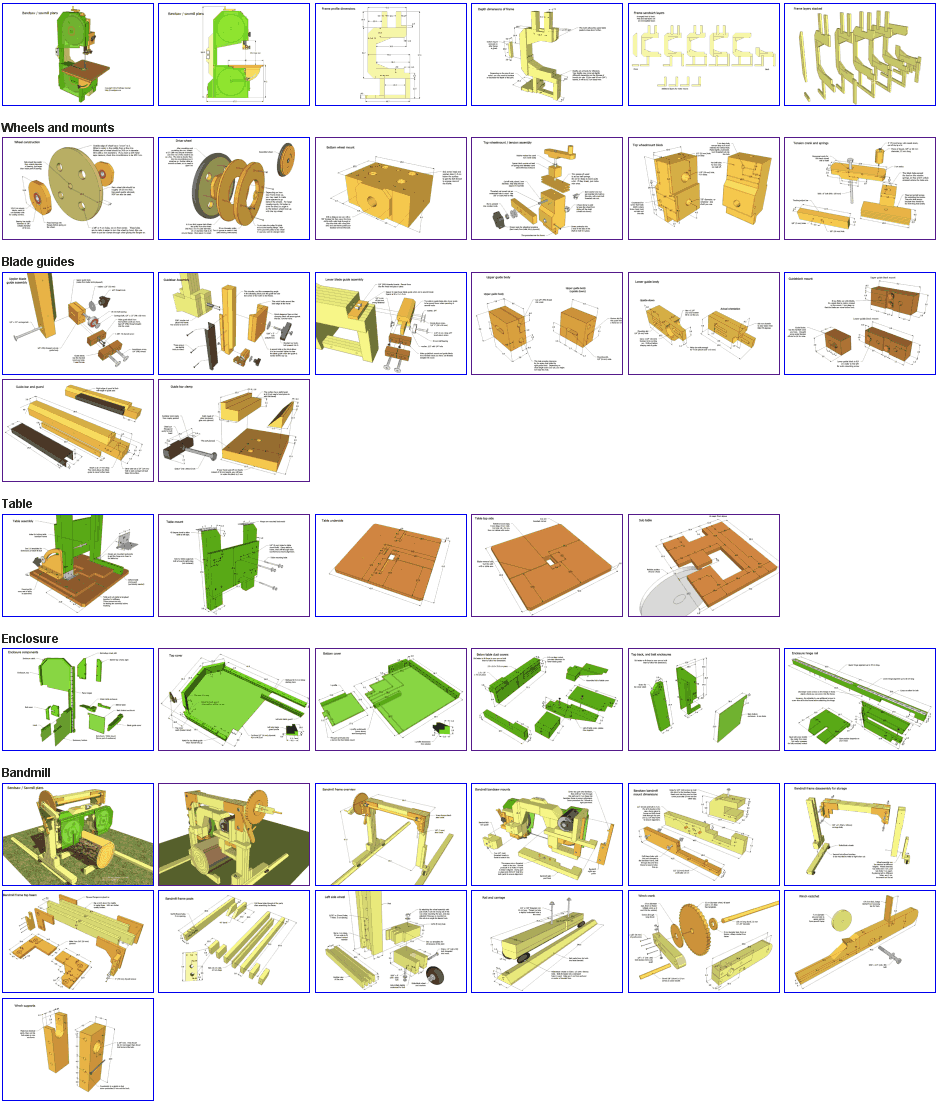

14 bandsaw / sawmill plans The 14 bandsaw/sawmill is a small light bandsw that can be used in your workshop, or on a special stand as a sawmill for cutting up logs. As a sawmill, it is light duty, comparable in speed and portability to chainsaw sawmills. Download your plans now, bandmil carriage, log loader, outdoor wood boiler. Click to visit Firewood processor plans. Bandmill carriage 65 drawings in PDF format. Pull behind your pickup and get the logs to your sawmill the easy way. This log loading trailer can self load and unload, all hydraulic design can be powered off your PTO added to. Saw_Mill_Plans.pdf (927.88 kB - downloaded 3350 times.) Logged Hilltop366. Senior Member x2. Bandsaw mill plans? Share Topic Similar Topics acme rod plans for bandsaw mill. 7021 Views May 15, 2016, 09:53:40 PM by Ox: Bandsaw Sawmill Plans Started by jerry-m on Sawmills and Milling. 4 Replies 4865 Views September 15, 2003, 05:52:27 PM. 14' bandsaw / sawmill plans for sale - woodgears.ca14' bandsaw / sawmill plans The 14' bandsaw/sawmill is a small light bandsw that can be used in your workshop, or on a special stand as a sawmill for cutting up logs. 14' bandsaw / sawmill build - woodgears.caThis bandsaw is only a 14' bandsaw (35 cm wheels).

Homemade Bandsaw Sawmill Plans Free

This will be my first Instructable, seems I never take a picture until the project is done ;-(

PLEASE comment and ask questions of you have them!!!

I have a camp property 29 miles from the edge of civilization, and therefore need to use my resources instead of driving back and forth trying to get just about anything. You plan ahead before going. Not enough beer? 58 miles. No propane? 58 miles...you get the idea. It gets worse when you have to hook up the trailer or take the big truck because you need more lumber to make some small project or build a barn. So, having access to plenty of logs, I need to make my own lumber. I have seen a zillion ways to make a band saw mill, but why not use something that has almost everything I need instead of building from scratch? The saw I am going to hack is a Craftsman 12' band saw. That means the wheels holding the belt are 12'. It already has all of the rollers, alignment adjustments, pulleys, etc. we'll need. I'll also be tweaking them a little for strength and longevity. I will be converting to a gas engine, so we'll remove the electrical equipment and save for another project.

The truth? I'm cheap. Well, maybe frugal. Wife says nuts (and brilliant depending on when you ask her). Still need a mill though. My best friends? Junk shops, junkyards, yard sales. The whole premise of our property is to do almost everything ourselves; learning about and understanding every phase of a project and the equipment, for as little money as possible to create a nice working farm. We are proof that you can do it while still staying out of debt. I found an almost free double wide home that needed work for a temporary camp while I build my barn and living quarters at one end of it, a backhoe and grade tractor, as well as a dump truck all for very little money. I could purchase a new mill for a few thousand, use someone else's design for a couple thousand, or design and build my own for a few hundred bucks. So:

Lets see: a workshop band saw is already.....a band saw, so???

I'll have to make a rail system

An adjustable carriage to hold the saw; able to raise and lower to cut different size boards.

Somehow attach the gasoline engine to run it.

A handle system for control and safety.

- Forum Actions

- Quick Links

Thread Tools

Display

- Aluminum

- Join Date

- Mar 2005

- Location

- Ontario, Canada

- Posts

- 108

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 0

Does anyone have any plans on building a verticle bandsaw or is a person money ahead to just go buy a used one at an auction? If anyone has pics of one they made or other home made ones please post them. Thanks.

- Hot Rolled

- Join Date

- Jan 2004

- Location

- chickamauga, GA

- Posts

- 896

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 2

Gilliom or Gillim or some such sounding company used to sell plans for a homebrew vert bandsaw. I think there's a Yahoo group that's got some pictures. Do some searchine for homebuilt machines in Yahoo groups for more details.

Really, they're not very expensive, I'd buy one.

Used 14' import woodcutters, $100

Used 14' American ones, $200 to $300

Honestly, a pac rim saw is just fine, take the time to really learn how it ticks and detail it into nice balanced quiet runner.

My used USA built 42' saw, $50! But that was different.

Metal cutters are a different story, however, if you're considering building a saw from scratch, converting a woodcutter to a light duty metal cutter might be a decent compromise.

Tools - Hot Rolled

- Join Date

- Nov 2002

- Location

- wright city, mo.

- Posts

- 586

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 7

SIR,

i have the 18in saw from GILLIOM,

and i have the jackshaft that is

used to cut metal. i did spend quite

a bit more beefing up the saw frame

than is required. they are located in

st. charles, mo.

wlbrown - Plastic

- Join Date

- Sep 2004

- Location

- corner brook, nl . canada

- Posts

- 5

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 0

I am in the process of building this band saw

www.frugalmachinist.com/3wheelbs.html

ed - matt_isserstedtDiamond

- Join Date

- Dec 2003

- Location

- suburbs of Ann Arbor, MI, USA

- Posts

- 13,038

- Post Thanks / Like

- Likes (Given)

- 423

- Likes (Received)

- 1011

If you can get your hands on a Powermatic model 143 in running condition, I would recommend that you do so.

It's built like a tank for its size.

-Matt - Jon_SpearHot Rolled

- Join Date

- Aug 2004

- Location

- San Francisco, CA

- Posts

- 985

- Post Thanks / Like

- Likes (Given)

- 27

- Likes (Received)

- 9

The bandsaw that Ed is making is very impressive.

I think that just making a simpler two-wheel bandsaw is a daunting project, one that would require a great deal of time. The 3-wheel saw described in the above link looks really nice, and I respect the amount of effort that goes into making it.

I believe I have seen photos of somebody using a pair of mag automobile wheels and turning them down on a lathe to be used as the bandsaw wheels. I think that would be much easier, and still pretty interesting as a do it yourself project. - Stainless

- Join Date

- May 2003

- Location

- Weirsdale, FL

- Posts

- 1,777

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 172

Ed, nice job.

Jon, I saw pictures some time ago of a bandsaw made using motorcycle rims. That sounds like a good way to go. - Junior Member

- Join Date

- Aug 2005

- Location

- Kansas City, MO

- Posts

- 25

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 0

Here's a 24' throat saw that I have built and have been working at converting the 3D drawings to 2D and still need to write the directions for it. It works well for sawing steel as so much of the blade speed is killed by driving a 6' wheel. It's 3 speed also and the top speed works well for wood. It's construction is pretty easy stuff and doesn't require anything exotic in the way of machinery. It's shown without the front cover so you can see some more detail. It has the drive wheel on the lower left, the tension adjusting wheel on the upper right and the two tracking wheels on the upper left and the lower right.

- Aluminum

- Join Date

- Mar 2005

- Location

- So Cal

- Posts

- 183

- Post Thanks / Like

- Likes (Given)

- 2

- Likes (Received)

- 0

I've seen 3 shop built band saws. To me there is something heart warming about a hand built machine found still in service after 50 years, but that's just me. Yes they can be bought new for cheap, but maybe you like to design and build things, which is good. If I had the time I wouldgain all skills and build the machines I use, but alas I have no time.

- Cast Iron

- Join Date

- Jun 2005

- Location

- Reform Alabama

- Posts

- 440

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 1

George thats a really good looking bandsaw. Its simple and functional and thats what every machine needs to be. What size blade will it take? I would love to see a photo of the one you built. How would this saw compare the the 'legendary' DoAll's of the same size? You should but together a cd with cad drawings of these tools (I liked the tracer mill you made also) I would be your first customer. I believe anyone with fabrication skills could build that. Please give more pictures and details.

Chris - Junior Member

- Join Date

- Aug 2005

- Location

- Kansas City, MO

- Posts

- 25

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 0

Everyone,

Thanks for the nice compliments about the saw. I am sure that this will not keep up with a Do-All that might operate 8 hours a day, but it has served me well for a lot of years.

As I said, I am working at getting a set of plans made. It might take a little time though. I'm not much of a typist. I'll try to remember to post something when I get them done.

Chris, the blade for my saw is 107' long. It has a 24' throat. I make my own blades from a roll of blade stock. I have a blade welder. I've got kind of a funny story about that blade welder thatI'll have to post sometime. - Diamond

- Join Date

- Apr 2002

- Location

- Syracuse, NY USA

- Posts

- 9,652

- Post Thanks / Like

- Likes (Given)

- 18

- Likes (Received)

- 562

a friend made saw wheels for a Boice Crane that originally had phenolic wheels that cracked. he used ordinaly 14 inich grooved pullys, and used a v belt that he skived and glued into the groove for the tire, works well. I also saw a large homebuilt that used a angle iron frame that was a full gantry style, ie closed vs c framed, much stiffer. Annother customer or mine needed a 48 in throat, he took a ML I had , fabricated a deeper throat and a 3rd wheel, welded it all together, then cut the column out, works well, he does very exacting cutting of bronze sheets for sculptures he fabricates from sheet that you would think are castings.

- Stainless

- Join Date

- Jan 2003

- Location

- Imlay City, Michigan

- Posts

- 1,822

- Post Thanks / Like

- Likes (Given)

- 86

- Likes (Received)

- 179

I have several different saws for sale, some are projects and some are running.

The prices are $750.00 for an older 16' Do-All ML running or a 16-1 Do-All running(Ugly Paint)for the same price.

I have a powermatic project for $450.00, and also have a 14' Do-All band filer for $375.00.

I also have different Do-All carcasses available that would be great start for a saw project.

You can e-mail me if your interested [email protected] or call 248-396-5817.

I've got alot of projects and need to make room for some new ones.

Thanks, Kevin.

Quick Navigation

Quick Navigation General - ArchiveTop

General - ArchiveTop- Site Areas

- Forums

- Manufacturing Today

- Specific Machine Forums

- Open Discussion

- Commerce

- Machinery Manual, Brochure and Photo Archives

- Forum features

14 Bandsaw Sawmill Plans Download Free

Bookmarks

14 Bandsaw Sawmill Plans Download Free

Posting Permissions

Bandsaw Sawmill Plans Free

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off